Shearing is a simple mechanical method that utilizes a blade to trim the sides or make straight cuts. In contrast, laser chopping employs a concentrated laser beam that easily melts throughout the metal, resulting in precise cuts and negligible materials waste.

Regardless of the form, selecting the most suitable push brake for any fabrication project will rely on variables for example material prerequisites, production volume, and wished-for performance capabilities.

Sheet metal can be rapidly Reduce into 2D profile designs and shaped outside of several different superior-power supplies, making it great for fast tooling.

If the aspect must be bent at both equally ends and also the mid-portion, an extra Procedure is required. This is certainly completed on a hydraulic push or press brake. Normally, the sides on the element will turn out flat.

If you want an incredibly exact internal radius, it is healthier to employ dies with plastic inserts, which force the sheet metal versus the radius Instrument As a result staying away from untimely bending .

I'm consistently thinking, studying, and composing about these subjects, regularly striving to remain in the forefront of my industry. Allow my understanding and skills be an asset to your small business.

As the applying of sheet metal continues to grow, the look of sheet metal components has grown to be a important aspect of product improvement.

Having said that, it really is widely applied resulting from its flexibility and wide processing vary. It's placed on constructions with a straightforward construction, substantial quantity, or not too huge output.

This process can make sections with higher precision, which means small angle and straightness glitches. It is actually useful for buildings with intricate constructions, tiny volume, and mass processing.

It makes manufacturing quite challenging and manual labour may be wanted. However it fees over simple machining. As a result, it's wiser to opt for an alternate solution, if at all possible.

eight T to 2 T for sheet metal. Much larger bend radii demand regarding the similar power for bottoming click here as they do for air bending, however, lesser radii call for greater pressure—up to 5 moments as much—than air bending. Benefits of bottoming consist of larger accuracy and fewer springback. A downside is the fact that another Instrument established is needed for each bend angle, sheet thickness, and product. On the whole, air bending is the popular strategy.[2] Coining[edit]

The opposite method is tension Handle, which adjusts the tension of various deflection payment cylinders to create a reaction drive against the bending power at many points about the vertical plate in the workbench to avoid deflection deformation.

Sheet metal is a versatile product which has revolutionized how we build and design and style goods. From electronics to vehicles, sheet metal has uncovered its way into almost every market.

If you layout your bent sheet metal parts in CAD application that has a Particular sheet metal natural environment, use it. It exists for your rationale. When producing bends, it will require product specifications under consideration. All this data is important when building a flat pattern for laser chopping.

Emilio Estevez Then & Now!

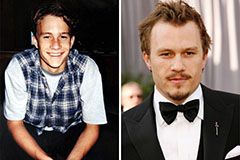

Emilio Estevez Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Seth Green Then & Now!

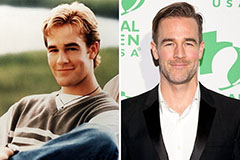

Seth Green Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now!